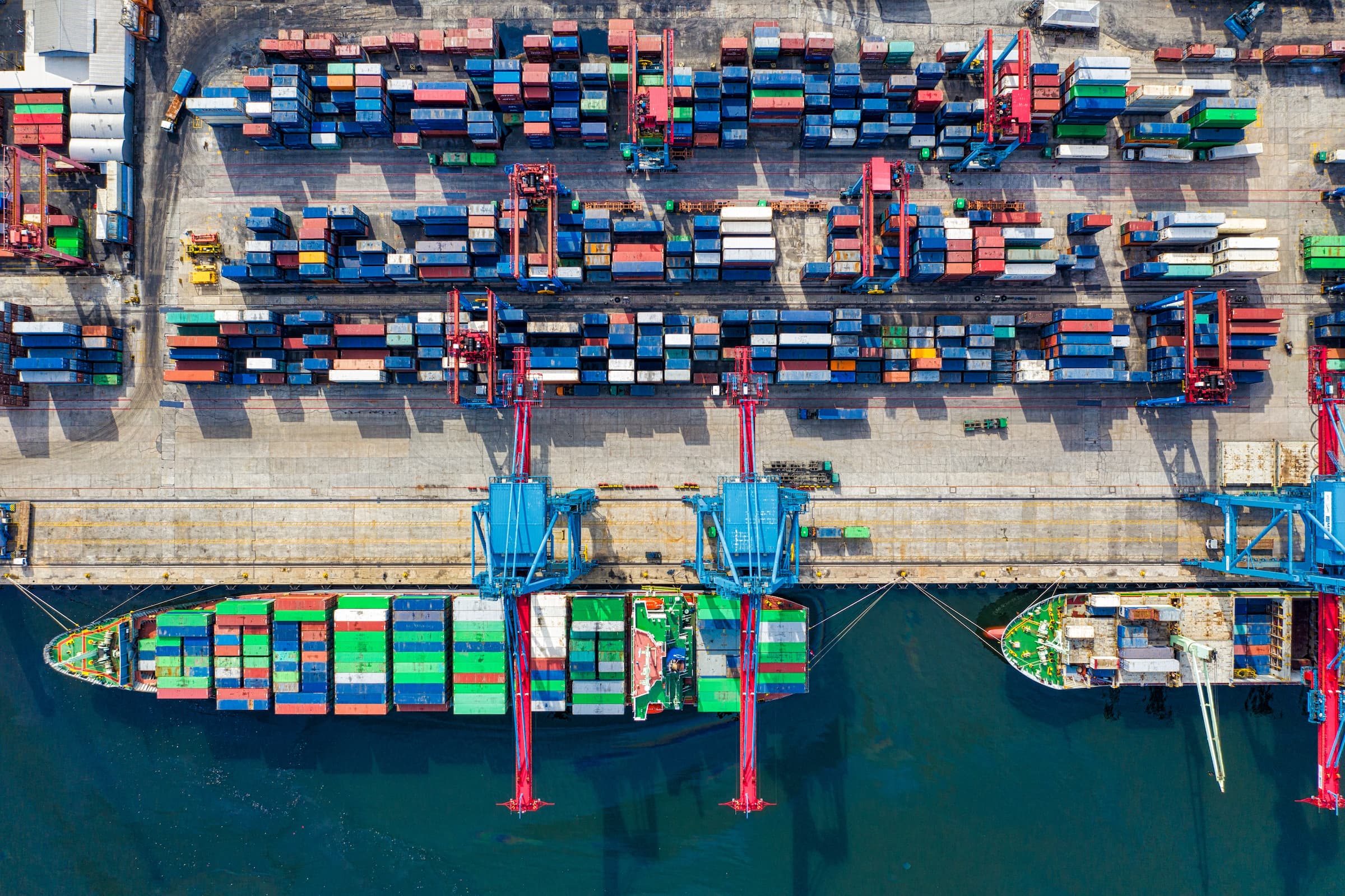

Vessel health management is about ensuring every crucial part of the vessel is inspected and maintained properly. It is critical to ensure safety and prevent incidents from happening. The current inspection system is easy to induce human errors due to factors such as subjective interpretation. Intelligent computer vision can help drastically improve the accuracy of vessel health assessments, reduce human error, and optimize the required follow-up work.

Automating tasks done by the human visual system is the goal of computer vision. However, even though AI is advancing rapidly, it is believed that we are still far away from having complete human-level artificial intelligence. Therefore, the most promising uses of AI will not involve computers replacing people, but rather, people and computers working together to do both cognitive and physical tasks that could not be done before.

What is computer vision?

Computer vision is one of the most powerful and compelling types of AI. It enables computers to identify objects and process images and videos in the same way that humans do in order to automate tasks done by the human visual system.

In the maritime industry, computer vision provides powerful solutions to applications that necessitate object recognition, including inspection, localization, event detection, and information extraction. Below are some of the advantages:

● Automate and enhance operations that are done by human eyes

● Detect anomalies and improve safety in real-time

● Increase performance through behavioural analysis

● Reduce cost through work automation and labor saving

One specific neural networks that are used in computer vision is Convolutional Neural Network (CNN). With large amount of label training data, CNN is able to break down the pixels in the images in order to seek for patterns. For example, detect and identify vessels on the ocean.

Challenges of using computer vision in vessel health management

Training computer vision to understand the physical world based on visual information such as images and video streams requires the development of algorithms for functions such as :

● Object recognition,

● Scene reconstruction,

● 3D scene modelling,

● Visually-assisted robot control,

● Motion analysis and

● Image restoration.

These functions presuppose improved computer-aided visual perception of the objects. However, there are many factors that can make effective target detection and feature extraction difficult. For example, lighting, movements, large changes in the image background, viewing angles, etc.

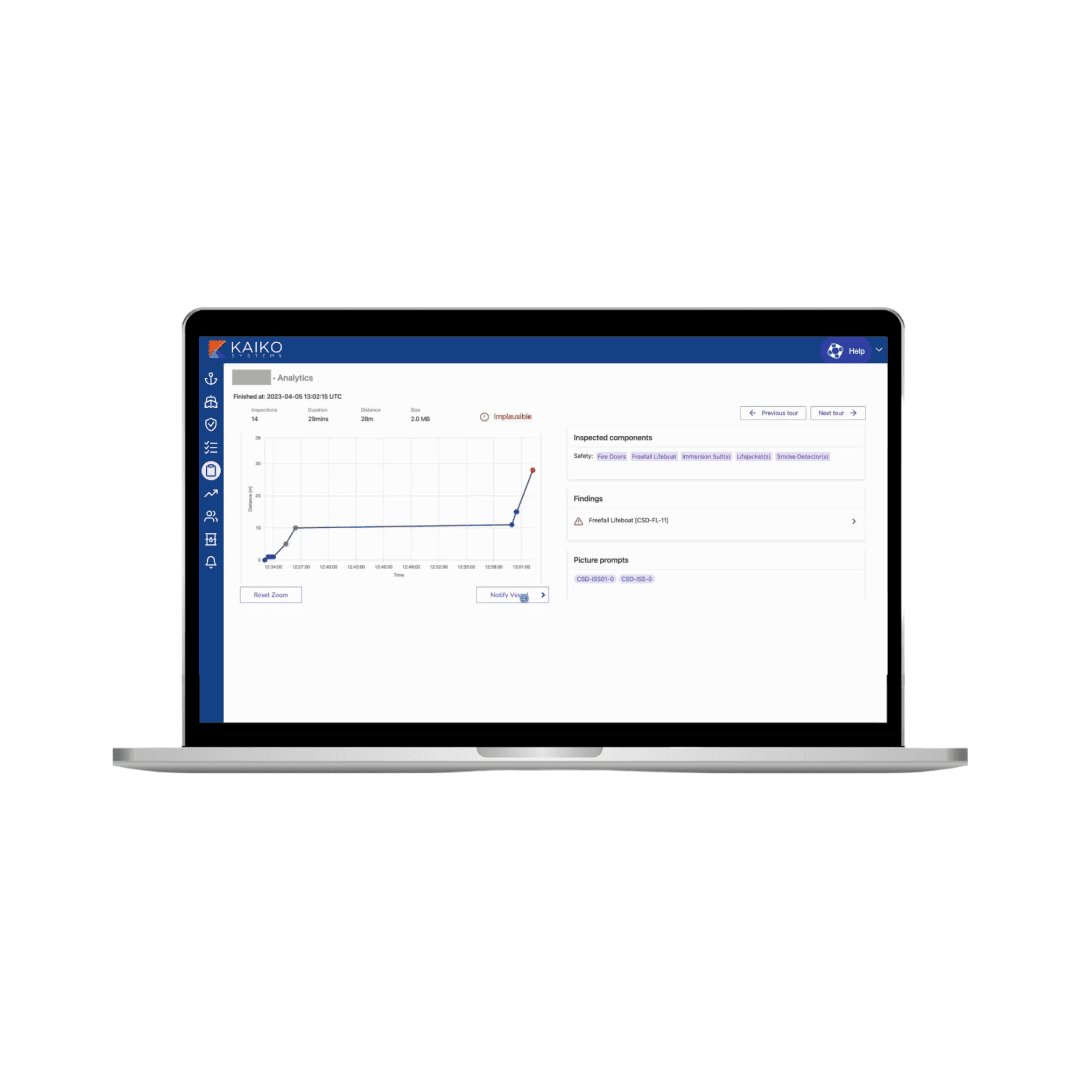

The Kaiko System Approach

To ensure the quality, consistency and predictability of maritime routine inspection data, Kaiko Systems empowers crews to collect verified and standardized data and images. With the human-centered design and In-App guidance, Kaiko Systems ensures pictures are taken from the same perspective every time with the right background, lighting, and scaling. In this way, condition trends and developments can be analyzed automatically.

For example, corrosion, as well as pitting and cracks are a clear indicator of the state of the hull metallic structures. Not identifying it can have catastrophic consequences both in personal, environmental and financial terms. Human driven corrosion detection can result in inconsistent and subjective corrosion analysis. Leveraging the visual aspects of roughness and color of the pictures, computer vision can deliver faster and more accurate corrosion detection.

How the algorithm works in a nutshell is visualized here:

In conclusion, a combination of human work and computer vision enables more proactive and efficient vessel health management. It can not only improve inspection quality by identifying problems early, but also save time and effort throughout the process by making prioritization easy.

References:

● Marine Vision-Based Situational Awareness Using Discriminative Deep Learning, Journal of Marine Science and Engineering, 2020

● Detection of corrosion on steel structures using automated image processing, M. Khayatazad, L. De Pue, W. De Waele, 2020

● Corrosion Detection for Automated Visual Inspection, Developments in Corrosion Protection, 2014

● A Benchmark for Deep Learning Based Object Detection in Maritime Environments, CVF, 2020