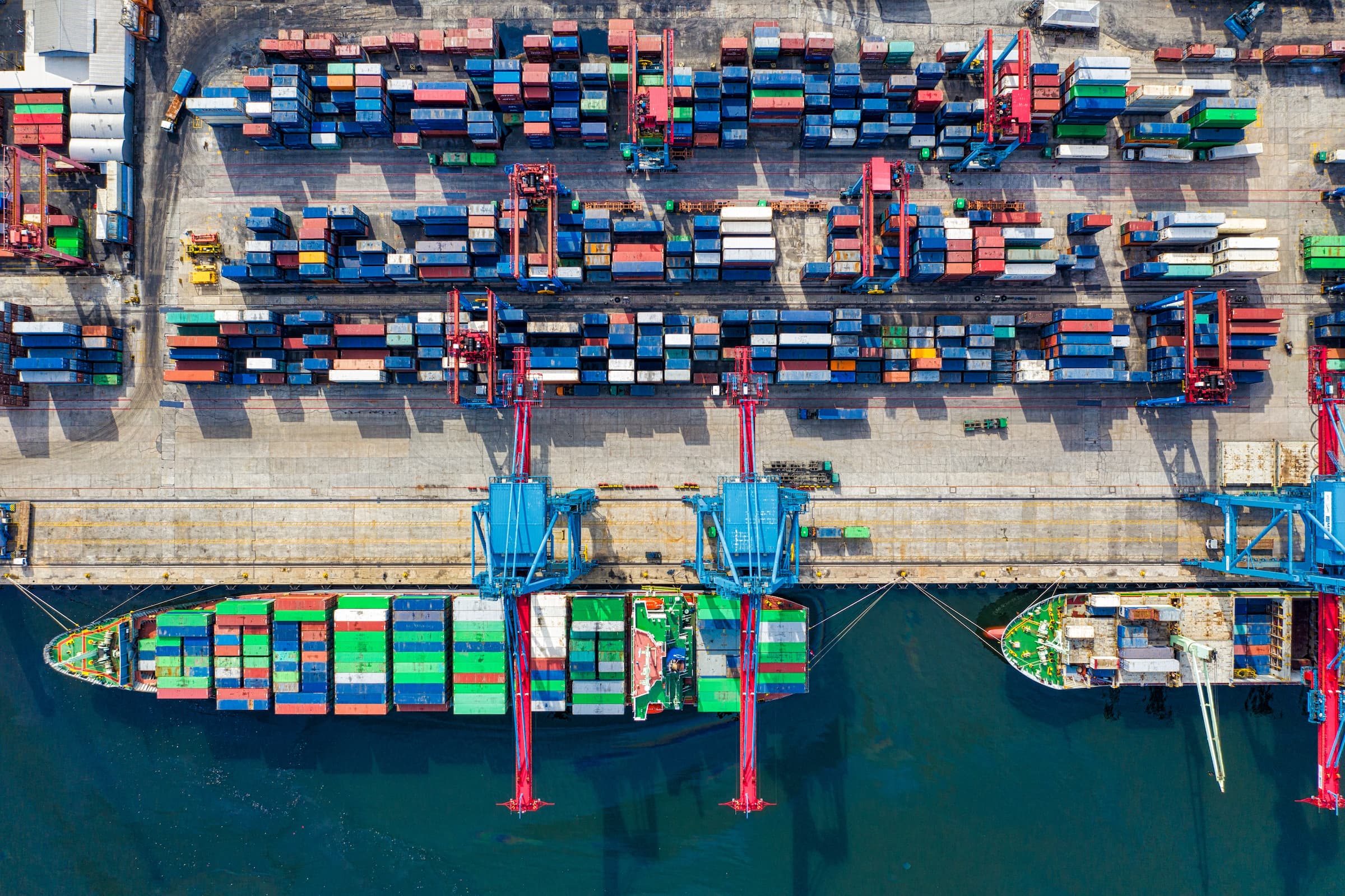

Maritime systems are typically operated in a harsh and largely variable environment. At the same time, failures in any of the subsystems or components may have large consequences. For example, when a lube oil pump fails, it could cost nearly 70,000 Euros to repair and take three days to do so, resulting in additional downtime and off-hire losses.

In the 2019 Safety And Shipping Review, AGCS analyzed 26,022 shipping incidents between January 2009 and December 2018. Of the incidents, nearly 9,000 were caused by machinery damage, such as engine failure, which is twice as high as the next most common cause. Machinery damage also accounts for 12% of the value of maritime insurance claims (over $1 billion in value).

With the feature of detecting anomalies before they result in failure, the concept of predictive maintenance has attracted an increasing amount of attention in the maritime industry.

What is predictive maintenance?

Before talking about predictive maintenance, it's helpful to understand the typical maintenance programs used on ships.

- Reactive Maintenance – repairing parts or equipment only after the asset has broken down or been run to the point of failure.

- Preventive Maintenance / planned maintenance - performing regular inspection and maintenance tasks while the equipment is under normal operation to avoid unexpected breakdowns and the associated downtime and costs.

Predictive maintenance is a condition-based approach. Unlike reactive breakdown maintenance, predictive maintenance can find anomalies and possible defects in equipment, components, and processes before problems happen. Normally, information is captured using sensors that are equipped throughout the ship. In this way, data can be collected in real-time, processed, and analyzed to alert any potential issues. But the industry has some obstacles to overcome.

The inherent problem with predictive maintenance for the maritime industry

Formula 1 racing cars have around 200 sensors and over 1.5km of wiring. If you compare the size of a racing car to that of a marine vessel, the sheer volume of sensors and wiring required for a single ship is a massive challenge. Take the graphic below as an example.

Human element empowerment

Is predictive maintenance through sensor & IoT data the only way to ensure high quality technical management?

We believe, that the human element remains the most important factor when it comes to improving quality & efficiency of technical management, safety & day-to-day operations. Regulations and guidelines are updated constantly for better human error management. Meanwhile, the tools that assist crews have remained the same for the past decades. This is like running the most advanced predictive maintenance algorithms with computers from the 1990s.

In routine inspection cases, many crews are still conducting inspections with paper, pen, and digital cameras. This process always lacks guidance and doesn’t support objective data collection, which of course leads to frequent human error.

Unlike machines, people have the agile ability and capability to deal effectively and safely with the complexity, difficulty, pressure, and workload of their daily tasks. This not only applies in emergency situations but also during routine operations.

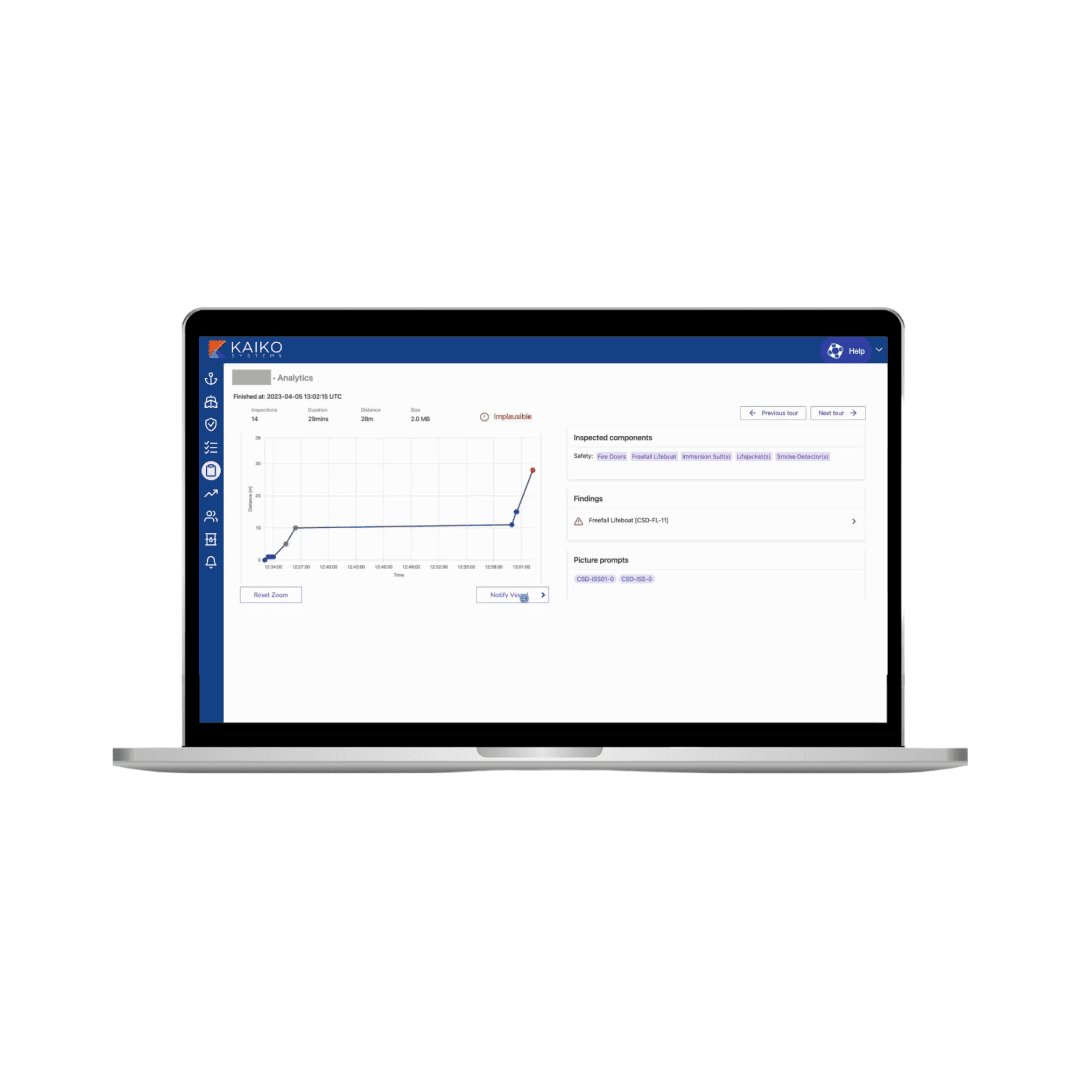

Our proposed solution is therefore, to equip frontline workers with tools that empower them.

What features does a tool need to have to better support human elements?

- User friendly: This ensures a fast adoption rate and the quality of jobs done

- Helpful: Tools need to save time for crews to perform their work rather than adding more unnecessary tasks and pressure

- Clear guidance in the tool: This can help remove bias and hence reduce human errors

- Consideration of other stakeholders: For example, the inspection data is standardized when it’s collected on the go, and clearly summarised and presented for the shore team when uploaded to the system

- Recognize the dynamic, complex nature of the situation: The tool needs to be able to function with a limited internet connection, and it should be easy to use in extreme working environments

- Ease of integration: To avoid duplication of effort and also allow data to be sesurfaced in the required systems

Why human empowerment is more vital than ever

Covid-19 has made many shipping companies realize now more than ever how reliant they are on the crews on-board for accurate information on the vessel’s condition. Digital transformation progress in the maritime industry has been accelerated by 3 years in 2021 and this technology transformation is mainly focused on operational optimization. Given the importance of the crew on-board, human empowerment will therefore be a fundamental driver for efficiency and margin gains.