- Kaiko Systems launches KAI, a maritime AI agent that sits on top the unique Kaiko Systems dataset

- KAI supports technical teams by providing higher quality data, more objective analysis and automatic advice

Kaiko Systems is set to revolutionise vessel health management and operations with the launch of KAI, a comprehensive maritime AI agent, supercharging productivity of technical management teams.

As the industry increasingly harnesses the power of artificial intelligence(AI), Kaiko Systems has answered the demands of clients and introduced KAI to support technical superintendents (TSIs), marine superintendents, and vetting managers.

Though superintendents are among the most valuable resources in shipping, they spend up to 65-75% of their time on tasks that don’t make use of their expertise. KAI is primed to reduce workloads and also increase the reliability of maintenance decisions by enhancing image quality and detecting issues early on, including corrosion, ultimately improving fleet performance and safety.

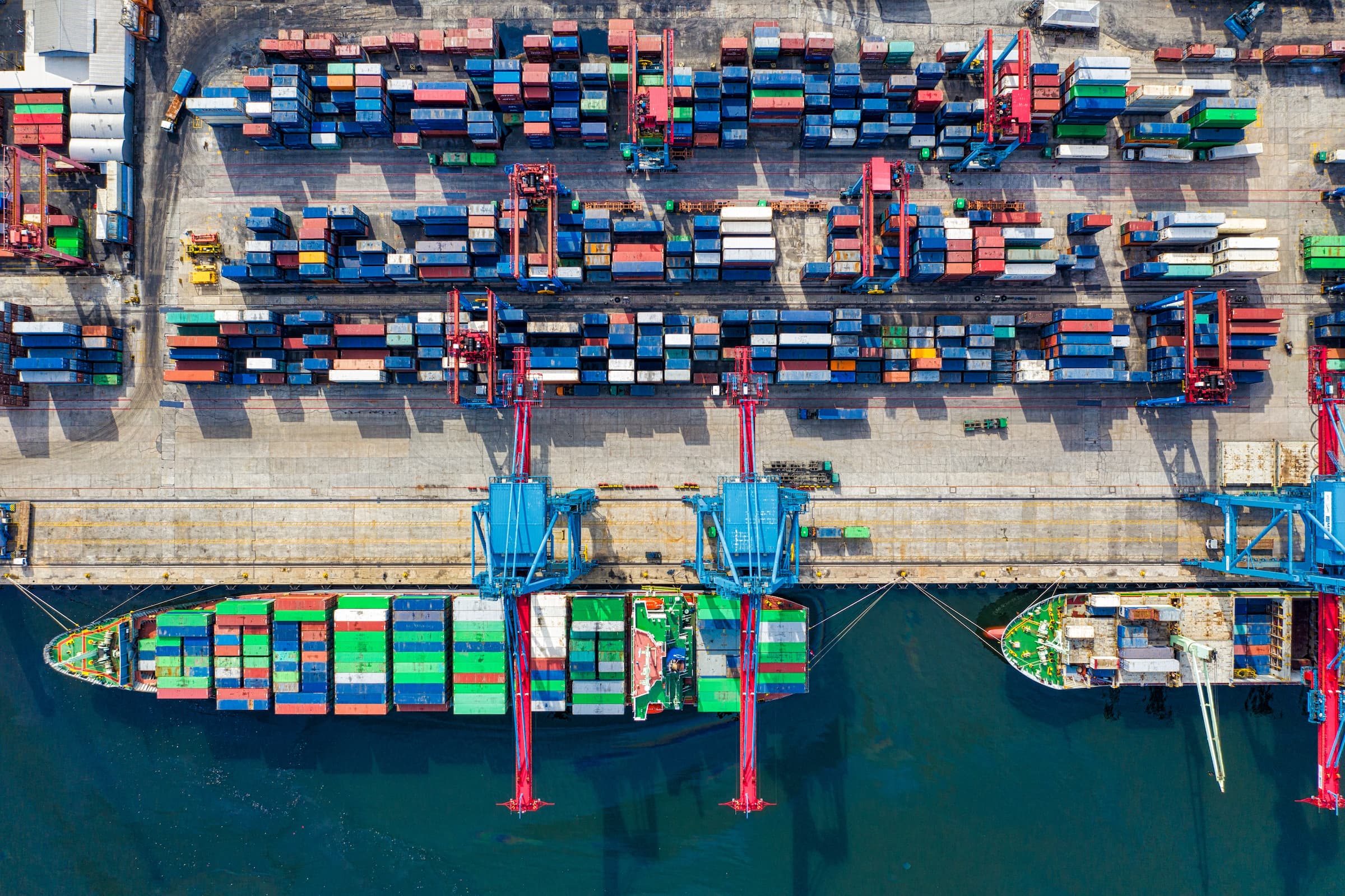

Vessel maintenance, especially when managed remotely, presents numerous challenges. Crew members often send reports and pictures to document hull and equipment conditions, but around 60% of these images are said to be difficult to interpret, leading to hours of email correspondence or uninformed decisions.

As of September 2024, companies used Kaiko Systems to send a staggering two million pictures from ship to shore for vessel health management. However, the main issue has been that camera algorithms are optimised for selfies and general scenes, which are ineffective in the specific lighting environments on vessels.

"Superintendents can only be in one place at a time, and check one datapoint at a time, but KAI can assess hundreds of images simultaneously, providing AI-driven feedback and summaries on vessel health. KAI provides superintendents with the data and insights they need to make informed decisions quickly, freeing them from time-consuming manual processes and allowing them to focus on making strategic decisions rather than getting bogged down in data analysis,” explained Fabian Fussek, Co-Founder & CEO, Kaiko Systems.

“KAI is more than a feature, he is a diligent team member, fully aware of every ship in the fleet.”

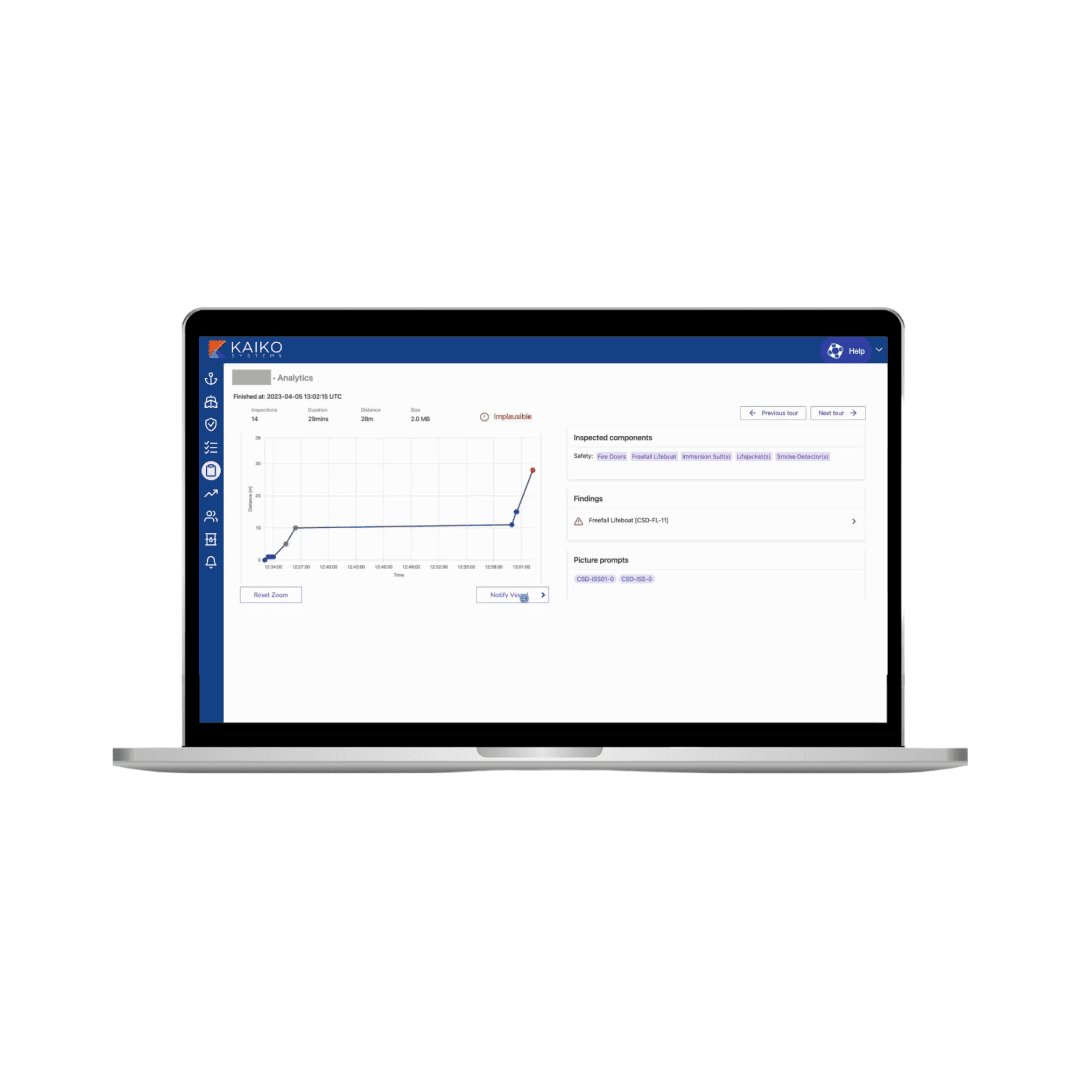

KAI enhances fleet management using several advanced capabilities: KAI Analysis, KAI Sight, KAI Corrosion, KAI Control, and KAI Chat.

KAI Sight enhances image clarity for better maintenance decisions, making vessel images easy to interpret by reassembling and restoring their quality.

.gif)

With KAI Analysis, hundreds of images per hour are assessed, providing accurate and comprehensive data, and automatic suggestions on next steps, while KAI Corrosion detects and measures corrosion, aiding in early detection and maintenance planning and significantly reducing the risk of undetected issues.

KAI Control verifies inspection data and ensures plausibility by reviewing crew reports and analytics, reducing human error and enhancing data reliability.

KAI Chat, which is available 24/7, provides vessel information, generates reports, and answers queries using natural language, always in full context of fleet and operational history, and sits on top of Kaiko Systems' unique dataset.

Following extensive trials, integrating KAI has already shown huge benefits, ensuring no details are missed particularly in complex lighting environments such as water ballast tanks and cargo holds. The first Kaiko Systems’ customers are already expanding KAI’s deployment fleet wide after seeing significant improvements in PSC and class inspections on vessels using the system.

KAI can be integrated into the existing platform seamlessly and Kaiko Systems is now rolling out an early adopter package for both new and existing customers.

Mr Fussek concluded: “The introduction of KAI marks a new era in maritime. We are fundamentally transforming how vessel maintenance is conducted.”

About Kaiko Systems

Berlin-based Kaiko Systems GmbH was founded in late 2020 to make shipping safer, smarter, and more collaborative. The tech company has developed a smart and user-friendly data collection and analysis tool that provides shipping companies and their stakeholders with comprehensive insights into the manual part of technical operations, such as inspection and maintenance. With a user-friendly mobile app, crews are able to continuously collect reliable technical data on the job. The automated, AI-based analysis then provides shore teams with data-based insights on potential risks and efficiency gains. Disruptions and downtimes of ships can thus be reduced. For more information, visit www.kaikosystems.com