Most maintenance software runs on computers that are placed on the bridge. This means that all planning and reporting has to happen on the computer.

Before conducting the inspection, crew members have to check which inspections are due on the computer, print out the checklists, take their camera, and then conduct the actual inspection. This part alone can cost a lot of time and complexity.

After the inspection is done, crew members then have to type the inspection results into the computer and compress and transfer pictures manually. Only then the results can be sent off to shore.

This process has to be repeated every time something is reported, including when documenting and following up on deficiencies. It could be even more stressful when reporting takes too long and communication between ship and shore does not run smoothly. This adds an extra burden to crews that are already facing heavy workloads.

How does Kaiko Systems help?

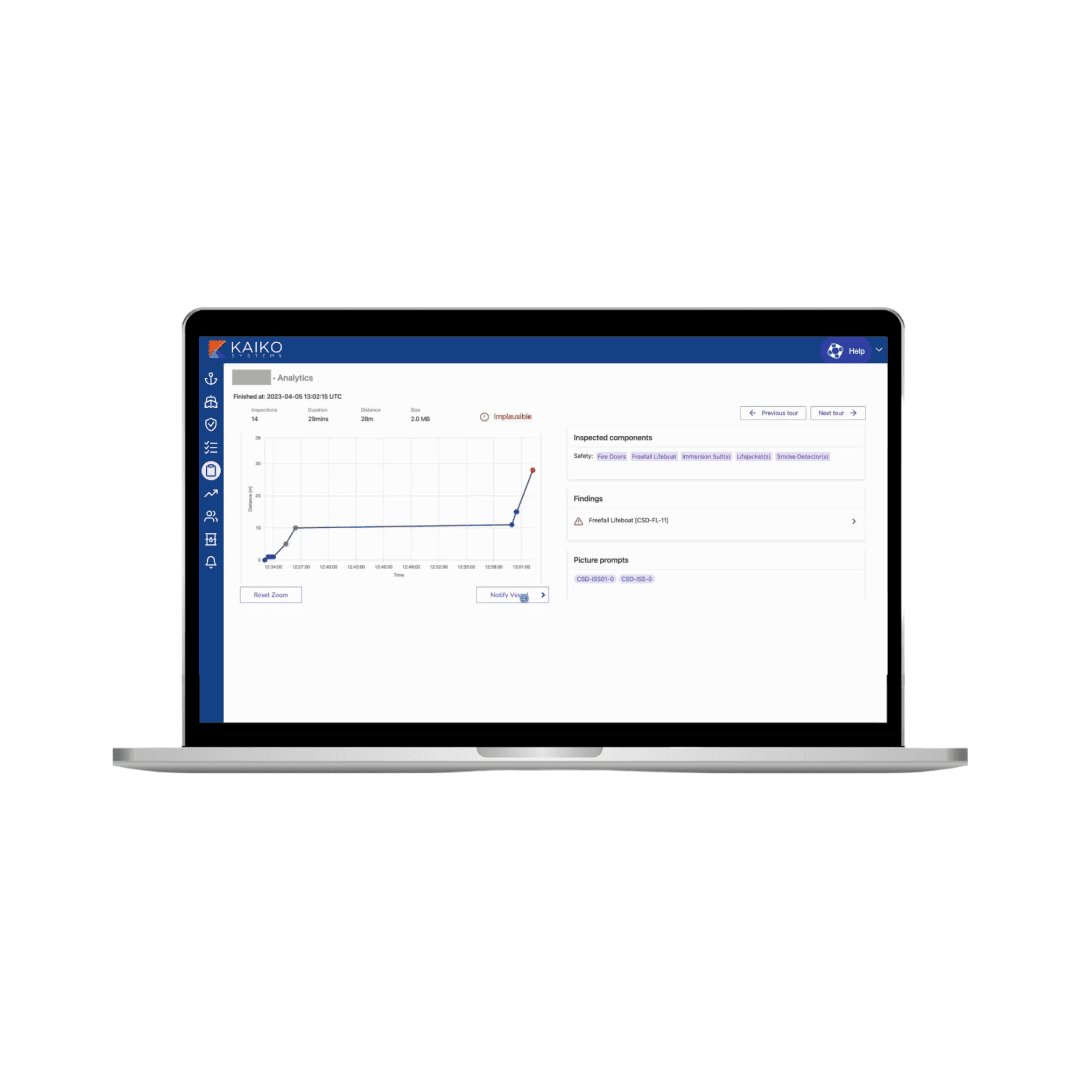

Kaiko Systems simplifies this process by providing a platform to plan, conduct and report the whole inspection on one platform.

With Kaiko Systems’ smart checklist, crews can be notified which inspections are due. When conducting inspections, crews are guided to check items off the list - taking pictures, rating deficiencies and adding comments during the inspection. To upload the inspection results like pictures and comments, crews don’t need to go through computers anymore. All they have to do is to press the upload button on the mobile App. This has removed gruesome administrative work in the inspection process and crews have reported saving of 50% the time.

On the other hand, the shore team can see the inspection results immediately and gets notified when a deficiency is reported. In the user friendly dashboard, the shore team can digest the information quickly. In addition, vessel health visualizations provide condition trends over time.

To further facilitate the rectification, Kaiko Systems allows the shore teams and crews to add information like root causes, damages and corrective actions to deficiencies. They can also communicate directly on specific deficiencies.

Reach out if you want to learn more about our solution and how safety tech can help you improve efficiency and reliability.