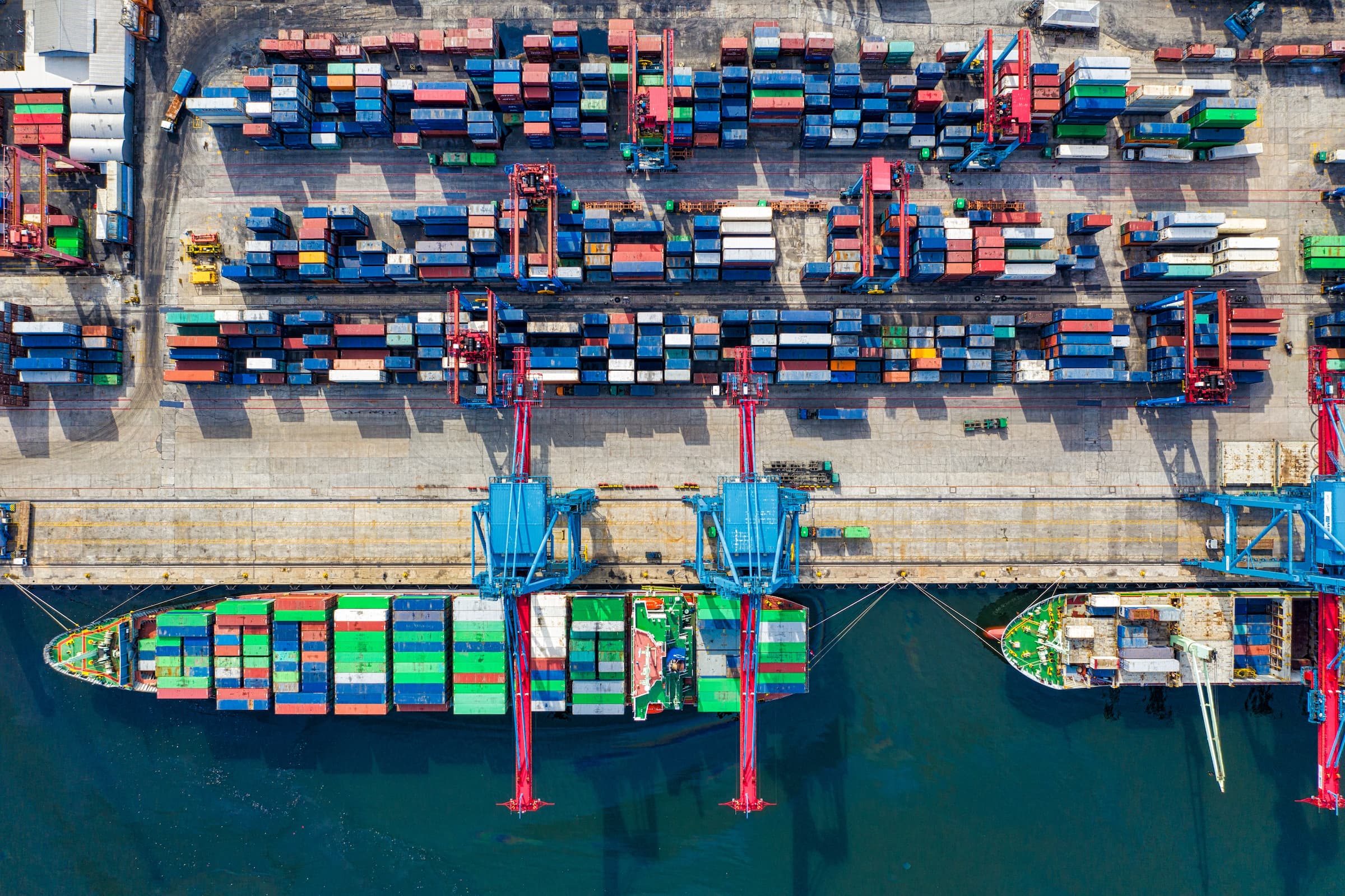

Safety is the most substantial and critical issue for the maritime industry. Allianz Safety and Shipping Review 2022 pointed out that on average 8 shipping incidents are happening every day, and every 7 days a ship sinks. To address potential safety issues, maintenance is taking place regularly. But current procedures are siloed, lack reliability and standardization of data sets, offering only a descriptive way of analysis. This leads to the situation that the shore team is firefighting the majority of the time and can only deal with issues, accidents and incidents when they actually occur.

Primary challenge on safety related data analytics

The main challenge associated with safety and maintenance analytics is that much of the data is scattered across enterprise resource planning (ERP) systems, case management systems, legacy purpose-built safety applications, and various other secondary sources, such as equipment maintenance management systems.

Additionally, much of the data is stored in different formats - free text, pictures from different angles, and is subject to schedules, making it challenging to gain an ongoing holistic view of how the current maintenance system impacts the asset health condition.

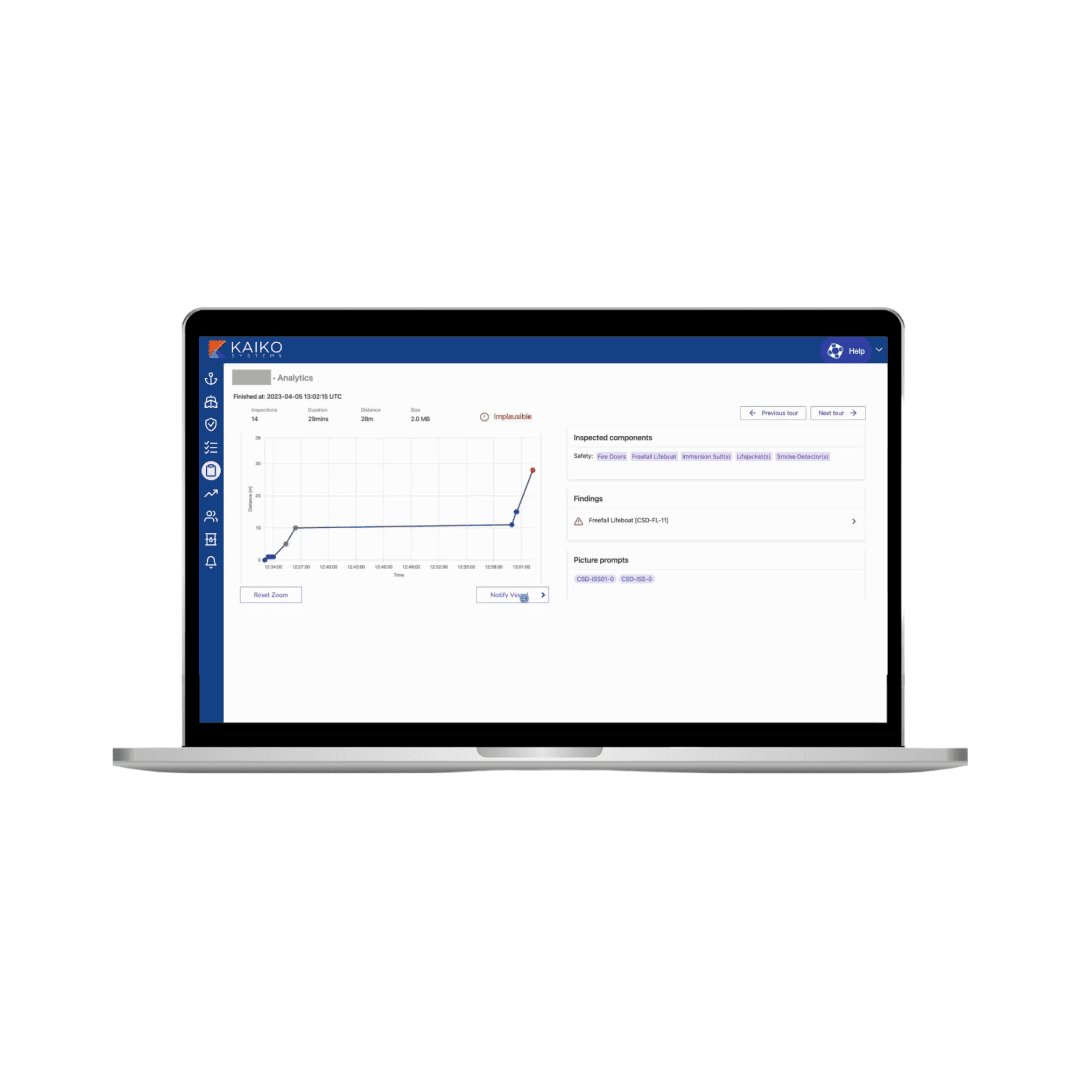

To be able to analyze factors that might potentially result in deficiencies, it’s important first to optimize data sources and structure them into a concise data set. This then allows companies to view raw data from distinct analytic perspectives. For example, to conduct root cause analysis, Kaiko Systems allows technical teams to create a timeline from normal operation to when the failure occurred. Variables like time, components, maintenance schedule can be structured and correlated throughout the timeline.

How standardized data sets foundation for safety and efficiency

The goal of technical operations is to prevent incidents, reduce downtime, increase safety and overall efficiency. To achieve this, technical teams move towards a proactive approach, which means to anticipate issues and take actions prior to an actual incident. To enable proactivity, shore teams need to be equipped with the right tools that are able to provide predictive or prescriptive analytics. However, with current systems in place it’s very challenging to make a leap to predictive or prescriptive analytics, because the data collected lacks reliability, standardization and structure. In current technical operations, it requires many hours from TSIs to conduct manual analysis based on inspection reports and planned maintenance systems records.

Standardized data sets provide a common language for technical operations teams to communicate, collaborate and make informed decisions. By standardization, teams can ensure that everyone is working with the same information, regardless of location or role. This leads to better decision-making, more efficient operations and a reduced risk of human error. Additionally, standardized data is more easily integrated with other systems and tools, such as AI-based or predictive maintenance algorithms. This allows for a more holistic view of the equipment and systems being monitored, leading to data-driven decisions and improved safety. Ultimately, the foundation of standardized data sets is critical for technical operations to advance to the next level of analytics and achieve greater safety and efficiency.

Kaiko Systems enables crews and shore teams to collect, categorize and verify data from onboard operations. Through digitization of routine inspections and checklists, technical teams can advance further to the level of predictive and prescriptive analytics. That means that shore teams will be able to forecast potential issues, get instant suggestions on actions and prevent incidents before that actually may occur.

Optimizations that bring value from day 1

An immediate optimization is to engage with tools and technologies that facilitate data collection, standardization and advanced analysis. In Kaiko Systems' case, the solution enables crews to collect data onboard in a standardized way, allowing shore teams to get a holistic view into technical operations. The platform structures and verifies inspection and maintenance reports and supports technical teams in data-driven decisions from day 1. Shipping companies who transformed their approach to data management, benefit from optimized maintenance schedules, reduced downtime and off-hire, and increased vessel and crew safety.

In conclusion, the foundation of standardized data sets is critical for enabling data-driven decision-making, reducing the risk of human error, and facilitating the integration of other tools and technologies. By collecting, structuring and standardizing data, shipping companies can have more efficient and technical operations.